| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : KEYE

Model Number : KVIS

Certification : NO

Place of Origin : China

MOQ : 1 SET

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 1 set per 4 weeks

Delivery Time : 4 to 6 weeks

Packaging Details : Fumigation-free wood

Name : CCD Visual Inspection System with Stroboscopic Light

Weight : 500 kg

Warranty : 1 Year

Condition : New

Showroom : None

Technic scheme : Provided

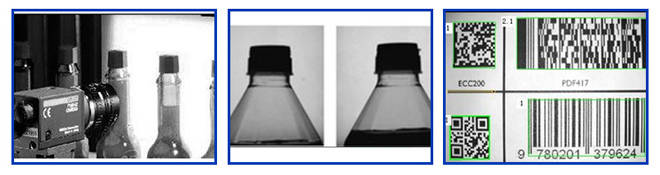

Applications : Bottle caps

After-sale : Remote service

MOQ : 1 Set

Payment : T/T,L/C,Paypal,Credit card

Advantages of system

| 1.AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2.Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3.Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4.High precision: detection accuracy can be high |

| 5.Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6.Easy to operate: It is easy to operate and easy to maintain |

| 7.Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Inspection principle

In order to adapt to today's increasingly fast-developing society, machine vision detection technology is essential. And machine vision inspection has become an important role in the process of industrial automation production, especially for some large-scale production enterprises, through machine vision to replace the traditional manual visual inspection method, identify product defects, and real-time product production quality data Carry out monitoring to reduce defective production, ensure product quality stability and improve market competitiveness.

The most basic feature of the machine vision system is to improve the flexibility and automation of production. In some dangerous working environments that are not suitable for manual operation or occasions where artificial vision is difficult to meet the requirements, machine vision is often used to replace artificial vision. At the same time, in the process of large-scale repetitive industrial production, the use of machine vision inspection methods can greatly improve the efficiency and automation of production.

Machine vision detection classification:

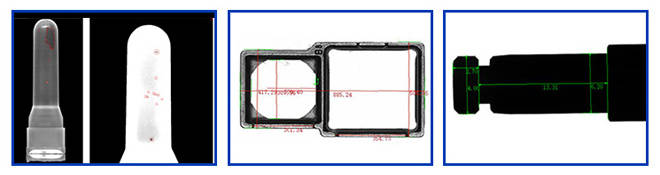

1. According to the detection function, it can be divided into: positioning, defect detection, counting/missing detection, size measurement.

2. According to the carrier installed, it can be divided into: online detection system and offline detection system.

3. According to the detection technology: usually there are size measurement technology, appearance surface defect detection, OCR technology and so on.

Machine vision inspection application case:

1. Visual inspection of battery products: detection of appearance defects such as foreign objects, scratches, indentations, bad tabs, pollution, corrosion, pits, tab burns, bad coding, blurred characters, etc. of battery products.

2. PCB circuit board visual inspection: PCB circuit board product shape, size, pin and patch inspection, as well as integrity inspection of solder joints, direction errors, etc.

3. Visual inspection of precision parts: measurement of length, width, height, diameter and other dimensions of precision parts such as screws, bearings, gears, etc., and detection of surface defects such as scratches, scratches, defects, etc.

4.Visual inspection of food packaging: Appearance integrity inspection, barcode identification, and tightness inspection of food packaging; beverage sorting and color sorting, liquid inspection, character recognition of production date and shelf life; empty bottle damage on filling line, cleanliness inspection, etc.

|

|

CCD Visual Inspection System with Stroboscopic Light for Quality Control Images |